By Rebecca Hellweg, Sales Representative, Pellenc Australia

Known for their harvesting and sorting systems, Pera-Pellenc delve further into the cellar, developing smart technologies to increase automation and efficiency for winery operations.

Traditionally, labour costs have been the biggest driver in regard to the simplification and streamlining of processes in the cellar. In a time of social distancing, and the new “COVID normal”, the concept of automation in the cellar is one which has become much more important, and one of interest from the largest to even the smallest of cellars.

Pellenc is a French group which was founded in 1973. With the purchase of Pera in 2014, and their own 120 years of innovation and experience, the Pera-Pellenc group have become an international force, leading the pack in both the vineyard, and cellar equipment.

With a worldwide presence, and a close relationship with their customers and their needs, Pera-Pellenc continues to innovate and revolutionise cellar equipment through the development of their Smart automation range.

The Smart range includes three main areas for integrating automation into the cellar. These include,

- Smart Oak: a process for hassle free oak integration for finished wines

- Smart Glass: transfers made easy by an intuitive sensor fitted to your existing pump

- Smart Press: the utilisation of information from past pressing cycles to make decisions for better pressing and efficiency

Pera-Pellenc at a glance

1495 employees worldwide

16 subsidiaries including 6 factories

10 M€ invested each year in R&D,

113 people working in R&D

884 patents

Smart Oak

Smart Oak is an automated tool for managing the oaking process. The Smart Oak system includes an oaking tank, a pump and built-in sensors that improve the speed, control and ensure repeatability of the oaking process.

A variety of wood fragments can be used including wood chips, staves and blocks.

Smart Oak aging is completed in a few days rather than months. The winemaker chooses the type of oak and sets the intensity level by using the simple, easy-to-use interface.

We see a reduction in labour costs associated with the removal and disposal of oak alternatives, but also faster turnaround of tanks and finishing of wines for bottling.

Quality

- inert environment during aging

- preserves freshness and fruitiness of wine

- controlled extraction of aromatic compounds from the oak

- temperature monitoring in real time

- alerts in the event of uptake of air

- extraction intensity selected according to the variety and level required

Cost effective

- Reduced wood/wine contact time (a few days instead of 3 to 6 months in the static process).

- Rapid return on investment.

- Flexibility: enables fast adaptation to consumer demand.

- Improved control of wine preservation (no transfer from tank when oak aging with alternatives).

Efficiency

- Oak added to the Smart Oak tank.

- No need to lift bags of wood chips to the top of the tanks.

- Safe for operators.

- Customized control of oak aging.

- Automatic or manual cycles.

Comfort

- The progress of oaking is monitored by the integrated sensors

- Repeatable wood aging profiles.

- User-friendly and intuitive touchscreen interface

“Smart Oak helps to oak the wine for the optimum period of time,” explained Jean Luc Andrieu, director of Cave Héraclès in Gard, France.

“Smart Oak provides a response to an urgent, unplanned demand for oaking. The organoleptic result still complies with current practice. The oaking is also repeatable. Smart Oak is easy to use and implement. The wine keeps its fruit and its aroma, while adopting volume in the mouth and added structure.”

Smart Glass

Smart Glass is an intelligent, connected sensor for automatic control of liquid transfers.

The Smart Glass solution consists of two interacting elements:

- Smart Glass – the intelligent, connected sensor

- A pump pilot module for controlling the pump; this receives data from the remote control or from Smart Glass.

Smart Glass will detect a change in the liquid and notify the operator in real time. If Smart Glass is paired with a pump pilot, it will send an order to stop the pump if it detects any change in the liquid.

Possible applications include:

- Tank racking – detection of water versus products versus air

- General transfers – water/air detection

- Tank topping – via remote control on pump

Quality

- Preservation of the organoleptic quality of the wines: detecting air intake, liquid change during racking, settling or water-drive

- Homogeneity of blends

- Secure transfers

Cost effective

- Optimisation of cellar work: no need to stay by the tank during transfers.

- Optimisation of cellar resources.

- Reduced water consumption.

- Usable all year round for all transfers

- Automatic transfers

- Reduced wine losses

Performance

- Easy to use

- Parameters set as required

- Operator safety

- Real-time notification

- Automatic pump control (if paired with pump pilot)

Comfort

- Precision

- Safe transfer operations

- Simple technology for use with many applications

- Real-time information

Smart Press

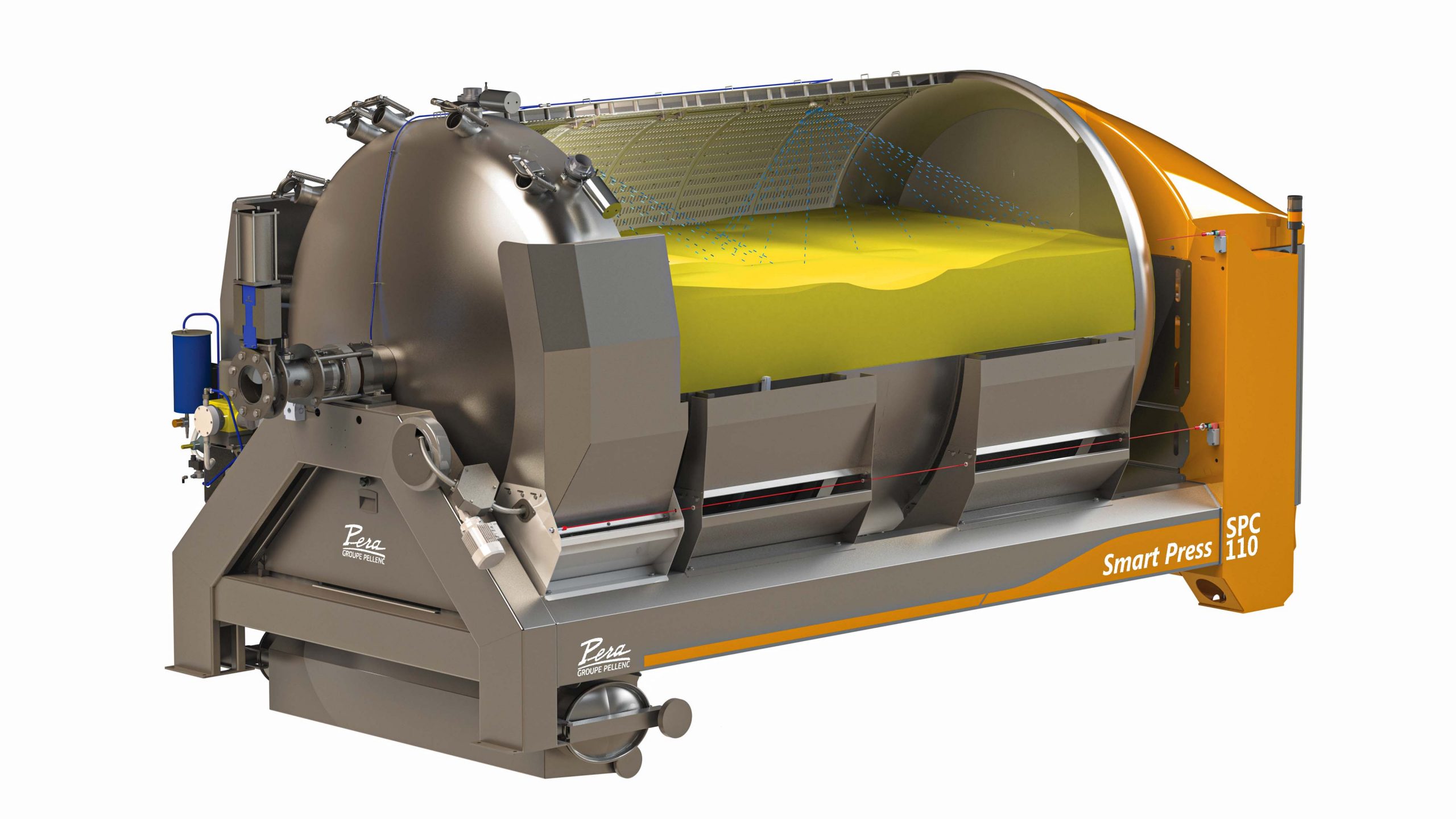

The new Smart Press range of pneumatic presses meets the needs of the most demanding winemakers.

Equipped with the latest innovations from Pera-Pellenc, including Fast Press drainage trays and the smart pressing system, we are able to optimise use of the Smart Press to extract high-quality juices.

The Smart Press pneumatic press range is available for all cellars, from 20-600hl in the closed cage version, and 40- 150hl in the open-cage version.

In terms of automation, there are two main features which allow winemakers not only greater insight into their pressing process, but also the ability to adjust processes for greater efficiency as well as time and labour saving during harvest.

Easy Press

Easy Press – the new intuitive Touch Press tactile interface and the Easy Press 2 smart pressing system simplifies use from the outset:

- Pressing cycles customised to meet the needs of the cellar (logistics, quality, etc.)

- Real-time adjustable pressing programme

- Saving of programmes (in advanced mode) on a USB memory stick for perfect traceability

- Customisable pressing cycles based on two criteria set by the operator: quality and dryness of the pomace

- Real-time information on any problems for faster response time by operators

Smart Graph

Smart Graph- a decision-making aid that allows the winemaker to understand and optimise the pressing. It enables a real-time diagnostic directly on the screen on the press, or later on a computer with Smart Graph software. By analysing the curves, the winemaker can get an understanding of problems arising from filling, clogging, etc. and take steps to optimise the various pressing phases (filling, drainage, pressing and so on). This has a direct impact on the quality of the wines (quantity of lees and juice extraction time = limits oxidation) and as well as decisions regarding harvest dates.

Optimising the various pressing steps has a significant impact on the pressing time. In many cases, it shortens the pressing process and saves the cellar a considerable amount of time.

Smart Graph lets the user visualise the progress of the pressing process in real time. The following information can be displayed as a curve:

- Pressure applied by the membrane

- Axial feeding pressure (in the case of axial filling)

- Quantity of juice extracted

- Complete juice height (computer version only): percentage of juice run-off/total juice according to time elapsed

- Antioxidant injection (if Enoxy+ option)

- Conductivity (if equipped with conductivity monitoring, available as an option)

- As well as three additional possible parameters (depending on options)

- The pressing data is stored on an SD card in the press interface.

Advantages of this information and system include:

Better understand the pressing process by visualising the various parameters as curves on a graph

- Have operational traceability of the pressing cycles

- Save time on pressing

- Optimise your pressing cycles (stages, rotations) in real time or afterwards

- Rationalise your harvest input = optimise the logistics of bringing in the harvest

For more information on the range by Pera-Pellenc and their Smart automation systems, as well as to speak to sales to discuss your site requirements, please contact:

Rebecca Hellweg

0497 999 973

Rebecca Hellweg

National Sales Representative, Pera Pellenc Winemaking Technologies

With over 12 years wine industry experience, as well as a B.Sc. (Agr.) and M.WBus, Rebecca is experienced in all facets of wine production, from harvest to bottle. She is passionate about helping winemakers to improve wine quality through automation and advancements in technology, whilst respecting the balance between the science and art of winemaking.

This free on-demand webinar is launched on 21 September 2020.

Register online here

This article was originally published in the September issue of The Australian & New Zealand Grapegrower & Winemaker. To find out more about our monthly magazine, or to subscribe, click here!

To view the current issue of the Grapegrower & Winemaker, click here.

Are you a Daily Wine News subscriber? If not, click here to join our mailing list. It’s free!