By Meg Riley

Working as a technical viticulturist in the Barossa, Amanda Mader was all too familiar with the downfalls of current yield estimation systems. In order to accurately record an adequate amount of data from the grapes throughout ripening, winemakers and viticulturists were having to make frequent trips to the vineyard, sometimes multiple times in one week, to collect berry samples and take them back to the lab for testing.

Berry samples could then be used to determine anything from ripeness and alcohol content to yield estimations and the influence of weather events or irrigation practices on the crop.

Back in 2007, Mader was working as a technical viticulturist for the Yalumba Wine company, where she was tasked with investigating alternatives to this method of crop estimation, with the goal of eliminating the need for such labour-intensive practices.

“Back in the day, E.J. Gallo were doing some pretty out-there work by measuring the tension on the trellis wire using load cells as a guide to yield estimation,” said Mader.

She and her colleagues got to work trialling this approach, however Mader said that this process involved “a lot of mucking around”, still required a high amount of hands-on work. Although this method of weighing bunches was convoluted, the results were extremely interesting to Mader and her colleagues.

“When we irrigated for, say, six hours, we were seeing an increase in weight on the canopy, and then as time went on by, the canopy would then decrease in weight,” Mader explained. “As a result of the tension on the trellis wires being measured by the load cell, the canopy was changing weight in response to climate such as heat waves and cold spells.”

Fast forward to 2020, and Mader was running her own viticultural business, Vinescout, and still mulling over the potential of bunch weight technology for crop estimations. She credited Dr Michael McCarthy, a viticultural scientist at the South Australian Research and Development Institute (SARDI) for planting the seed about the benefits that could be gained by measuring bunch weights in real-time.

“He said to me, ‘if you could nail something that could measure an individual bunch in real-time, you’ll become famous’.”

Mader reached out to a number of engineers, and in 2021 they had a prototype created and trialled.

“It wasn’t really real-time, because I’d have to download a CSV file of data every night, and add on the numbers on the graph,” Mader explained. She was determined to figure out a way to achieve real-time estimations, so that they could track the yields from any phone or internet-connected device and monitor fluctuations blow-by-blow.

Historically, obtaining berry or bunch samples to estimate yields has been a complex and time-consuming process.

For example, Mader explained that in the past, she would select around 30 vines in a block around three or four weeks prior to harvest, and count and weigh all the bunches, cutting off bunches to estimate how many bunches there were per vine, and the total weight.

“That used to take us forever, and then you would be wasting a lot of fruit to the ground, because you’re cutting your bunches to the ground.”

This data would then be manually entered into a spreadsheet, from which Mader would be able to ascertain a yield estimation.

How it works

Mader credited her business partner at RipenTech, Mason Erkelens, as the “genius” who made this technology reality. “I had the idea, but he actually made it happen,” she said.

Mason Erkelens developed a platform which uses a load cell to capture the weight of the fruit over time. Powered by solar and a lithium battery, the box fixes to a trellis post, and has an IoT (Internet of Things) sensor, which allows it to transmit data to the platform using the internet. Extending from the box is the load cell, from which hangs a line of copper wire, which is fixed to a bunch in order to obtain a weight reading.

“We had an opportunity to trial this technology in the Napa Valley last year in Cabernet Sauvignon, and we made the logger with three load cells to weigh three bunches at once. But what we found is it became too crowded, and the load cells were hitting each other.”

As a result, they came up with another plan.

“For this year’s logging, we made the logger with one load cell only, but then I’d quickly grab an average, say 30 bunches, to represent the vineyard,” said Mader.

This enabled them to gauge an average for vineyard, and then tension the copper wire to represent the average bunch weight, meaning that not as many load cells were required. The data can then be accessed through an application which Erkelens created.

Mader recommended that for growers using other monitoring devices in the vineyard such as a soil moisture probe, to place a logger in the close vicinity to the other technology, in a strategic area of the vineyard.

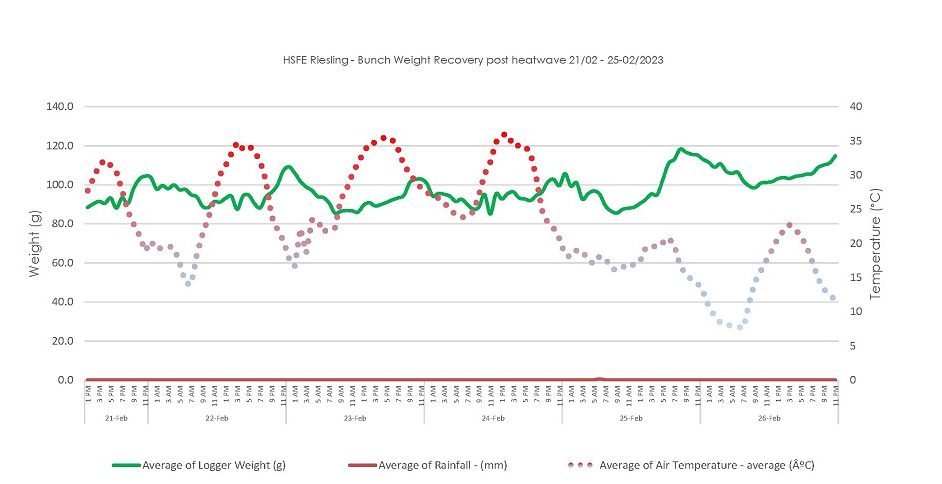

Fig. 1: Real time bunch weight response to a mini heatwave followed by a sharp weight increase in recovery once temperatures decrease significantly

Getting data smart

RipenTech aims to give growers and winemakers access to real-time data using less labour and minimising crop wastage. The real-time data provides a wealth of information about how a bunch is responding to external forces such as weather events, and can even demonstrate the efficacy of vineyard practices such as mulching or irrigating, allowing producers to more accurately predict and respond to yield estimations.

“As the rain is falling on the bunch, you can see the rate of increase [of weight], or if you’re viewing a heatwave, you can actually see the decline in the bunch weight,” said Mader.

“You can track the yield in real-time to really refine your yield accuracy when you’re delivering fruit to the winery. You can also view the impact of your irrigation application, to potentially improve your water use efficiency and save water for a sustainable future.”

This could help growers avoid or prolong berry shrivel by monitoring bunch weights, and intervening with an irrigation such as pulse irrigation before the berry has shrivelled.

“You can really fine tune your watering, because you’re seeing what’s going on,” said Mader.

With this technology, Mader said that all of these tests can be run without having to cut off any bunches, enabling collection of the data without the intensive labour.

“In the wine industry, what we say we’re going to bring to the wineries [compared] to what we actually deliver is within plus or minus 30 percent, so we’re way out with what we estimate [compared] to what we actually deliver.”

“If you have a heatwave, your yield could drop back by 30%, or if you have a rainfall event, it could increase by 20%. We just had no idea; we were just going in blind.”

These real-time estimations could help growers and winemakers to avoid fruit-weight loss during heatwaves, or run the risk of under-irrigating in drought conditions. Mader explained that it could also significantly reduce fruit wastage, as it eliminates the need to cut bunches from vines for yield-related testing.

“The grower is going to save time, because you don’t have to worry about labour-intensive data collection, and you can view your data on any internet-connected device in real-time. Then you [can] start to begin to understand your yield and ripening curves from season to season.”

Having access to historical data is another element of this data collection that Mader anticipates will be especially useful, as it would allow growers to consult their data from years with notable conditions such as heatwaves or drought, and compare the yield and ripening curves to understand and prepare for what to expect.

Yielding surprising results

Despite her extensive experience in viticulture, Mader has some of the results gleaned from the RipenTech trials have come as a complete surprise.

“In a day, sometimes we’re seeing up to a 30% decrease in bunch weights,” she said.

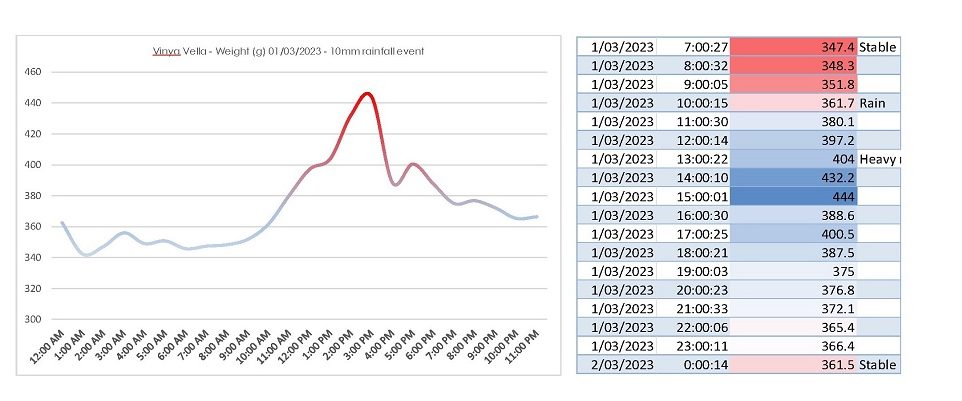

“We had a bunch logging in on a Grenache bush vine, and there was a 10ml rainfall event. We used to think it took two or three days for the bunch weight to increase after a rainfall event, but the bunch was increasing in weight as it was raining.”

With this information, the grower is able to observe if some varieties are quicker than others to respond to events such as rainfall or irrigation, and adjust their practices accordingly.

“We’re seeing Shiraz and Grenache certainly have a quick uptake, whereas varieties like Cabernet Sauvignon, which are anisohydric – that means they are pessimistic – they don’t uptake water straightaway, they seem to hold on to it. And you don’t see the rate of increase so much in Cabernet Sauvignon because of their properties.”

In one of the vineyard trial plots, monitoring the bunch weights also revealed the effect of different undervine treatments.

“One of the undervine sections had a lot of straw mulch underneath, and then another section just had tilled [soil],” explained Mader. “The bunch weight during a heatwave was way more stabilised in the straw section, in comparison to the tilled undervine section.”

Interpreting this data can arm growers and winemakers with information about the efficacy of their vineyard practices, and compare one site against another. This could also be used to inform on the performance differences of a variety between one region and another, said Mader.

“[With] a Cabernet Sauvignon bunch being logged in the Barossa, versus a Cabernet Sauvignon bunch being weighed continuously in the Coonawarra, there was a similar pattern between the two bunches in differing wine regions.”

Because the technology measures the weight of hanging fruit, it can also be applied to other crops outside of the wine industry, with the company trialling the system in citrus, avocado and apple farms.

“We trialled it in an apple orchard in the Adelaide Hills and got amazing results,” said Mader.

Preparing for commercialisation

As the device is trialled in more and more vineyards, Mader is able to pick up any issues that arise and work to minimise them. Just last year, RipenTech installed 15 of the devices for a company in New Zealand, a few of which were smashed as a result of mechanical leafers passing through the vineyard.

“But then, I’ve had a machine harvester that straddled it and it never got damaged at all,” said Mader. “I think that’s something that we’ll keep working on with regards to the design, to make it machine-friendly.”

High velocity winds can also be a problem, as they can create noise in the data. To combat this, Mader installs the device on the side of the canopy with the least exposure to wind, and use a program called ThingSpeak, which Erkelens developed to take the noise out of the data.

As they continue to undergo extensive trials in a myriad of vineyards and climatic conditions, RipenTech is now seeking investors for its patented technology, and is in preparation to accelerate its production in order to bring the sensors to the global market.

This article was originally published in the June 2024 issue of the Australian & New Zealand Grapegrower & Winemaker. To find out more about our monthly magazine, or to subscribe, click here!

Are you a Daily Wine News subscriber? If not, click here to join our mailing list. It’s free!