Chemical Plant & Engineering (CPE) is a division of CEM International, a world recognised manufacturer and provider of various process equipment solutions headquartered in Coolaroo, Victoria. CPE specialises in design, manufacture, and supply of various process equipment and has been the leading provider of wine agitators -VinFoil®– in Australia and New Zealand for the past 30 years. What makes VinFoil® outstanding is the technology behind the impeller design which has offered key process and quality improvements to the winemakers across the world.

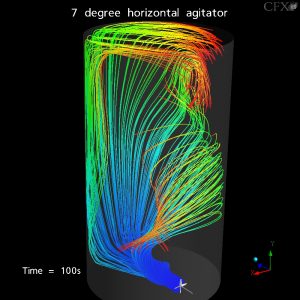

CPE’s high efficiency hydrofoil impellers are the best in their class in providing high velocity yet low shear flow using the minimum amount of power. Due to their special design, CPE’s hydrofoil impellers can create a fully “axial flow” within the wine tank which greatly helps with effective blending and solid suspension within the wine body in a short time. This results in considerably improved plant utilisation and savings in manufacturing cost and time. Many wine makers across the world have reported on noticeable improvement in their wine taste and quality as a result of using the VinFoil® technology. This can only be explained by an optimised agitation flow and duration inside the wine tank. Experimental data shows that the time to mix the wine blend components (chemical as well as concentrate additions into a wine batch) can be improved by up to 90 % by employing an optimised agitation solution. Similarly, in a typical blending application the time taken to reach full uniformity is a function of the flow being created by the agitator. This efficiency translates to less time in the tank – potentially freeing the tank for other uses.

Over the decades, VinFoil® has been offered to wine makers with the purpose of optimising various steps of wine production using “gentle” but highly efficient agitation solution. Examples of those process steps are fermentation, additive dissolving, solid suspension, blending and storage, flavour (oak, etc.) extraction, cold stabilisation, and micro-oxygenation.

Oak chip bags installed in tank for flavour extraction using VinFoil®

One of the challenges of producing wine is feeding the wine with uniformly distributed solid particles into centrifuge after fermentation. If the wine solids are not appropriately suspended in the wine body, they will settle at the bottom of the tank rather than travelling to the centrifuge. The precipitated solids then need to be removed before the tank can be re-used. This means maintenance cost and disruption in production.

On the other hand, if the wine solids are suspended in the wine body but not distributed evenly, this will lead to considerable fluctuation of solids content in the wine feed into centrifuge. As a result, the centrifuge performance will be far from ideal and additional maintenance time and cost as well as process disruption will be a major concern.

Luckily, CPE has been able to develop an agitation solution suitable for this challenge. The offered solution ensures wine solids are suspended uniformly throughout the wine body during the process leading to centrifuge feed. Thus, the wine containing solids is fed into the centrifuge in a steady and consistent manner. This minimises the tank and centrifuge maintenance time and cost while the plant efficiency is at its maximum.

This solution was recently put into test by CPE’s experts in collaboration with a highly reputed Australian winemaker. The trial results were pleasingly successful and since then CPE has been officially offering this solution to help the local winemakers get the most out of their wine production plants.

CPE can design and manufacture wine agitation solutions for any service condition and for various purposes, including mass transfer, heat transfer, blending, dissolving, and solid suspension. The amount of time and energy savings a traditional winemaking plant can make by switching from pumping to agitation is significant. Also, data obtained from wine agitator retrofit projects accomplished by CPE around the world shows that most existing traditional wine agitators can be replaced or modified by CPE’s VinFoil® technology to provide considerably better performance and efficiency.

Further to custom designing and testing capabilities, CPE seeks to constantly improve the quality and accuracy of the solutions provided to the wine industry using state-of-the-art process design tools and R&D activities both in-house and in collaboration with its large network of customers is Australia and New Zealand.

For more information about CPE’s wine agitation solutions and testing capabilities visit https://www.cem-int.com.au/cpe/agitators/wine-agitators/ or contact Max Dehghan on +61456754155 , [email protected] .