By Rocco Longo¹, Eveline Bartowsky², and Rob Gore³

Chitosan for winemaking processing

Over the past decade, there has been a growing interest in the use of “animalfree” chitosan agents in winemaking.

Chitosan is a natural (charged) polysaccharide obtained by deacetylation of chitin [poly-β-(1 → 4)-N-acetyl-Dglucosamine] under alkaline conditions, by a process patented by Kitozyme.

Chitin is the most abundant polysaccharide in nature after cellulose, and the main component of cell walls of fungi and plants, insect skeleton, and crustacean shells. Although chitosan is insoluble in wine (or water), only chitosan and chitin-glucan of fungal origin (from Aspergillus niger) is permitted in winemaking to prevent any potential allergic reaction caused by contaminants from processing crustacean material. Chitosan and chitin-glucan are approved processing aids in winemaking (OIV and FSANZ) and have been certified for use in organic winemaking (ACO).

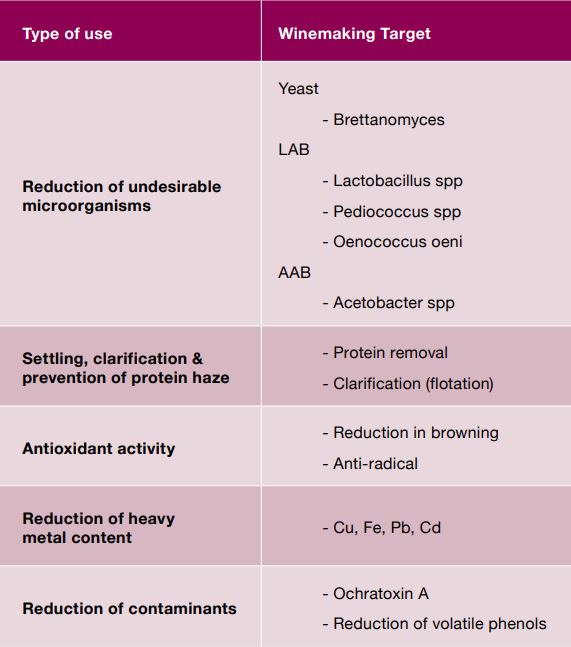

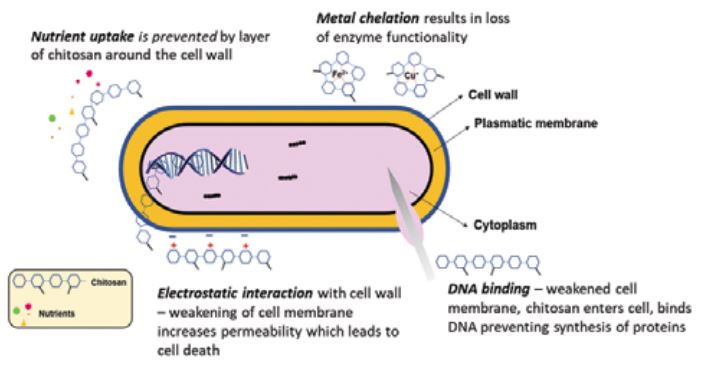

Fungal chitosan can be used for multiple winemaking purposes, as summarised in Table 1, from the treatment of excess copper contents and iron precipitates, responsible of undesirable deposits and/or hazes, to the inhibition of detrimental microbial developments, such as Brettanomyces/Dekkera spp., responsible of producing volatile phenols with unpleasant medicinal and horsey off-odours. In this article we discuss the various chitosan and chitinglucan products and their use during winemaking.

Control and elimination of microbial growth

Chitosan has attracted a great attention in the food and wine industry, in part because of its antimicrobial activity (Figure 1).

While still unclear, hypotheses of chitosan antimicrobial mechanisms include a change in cell permeability caused by the electrostatic interaction between the positively charged molecules of chitosan and the negatively charged molecules of microbe cell membranes (causing a leak of the cytoplasm constituents).

Other mechanisms include the interaction of hydrolysis products with microbial DNA (which causes the inhibition of the mRNA) and protein synthesis, in addition to the chelation of metals, spore elements, and essential nutrients (No et al., 2007; Marín et al., 2020).

This antimicrobial activity makes chitosan a very versatile product for food technologists. For example, it can be used for extending the shelf life of bread or the storability of perishable commodities (oxidation barrier effect), including fruits and vegetables when applied as an edible coating, followed by cold storage (No et al., 2007).

The chitosan products No Brett Inside™ and Bactiless™ are 100% natural nonGMO and non-allergenic chitosan biopolymers from fungal origins (100% Aspergillus niger), they help to reduce/eliminate Brettanomyces and spoilage bacterial populations in wine, respectively.

Chitosan has been demonstrated to effectively decreases Brettanomyces populations in wine (Tailandier et al., 2014; Petrova et al., 2016), and this effect can vary depending on the Brettanomyces strain (Paulin et al., 2020).

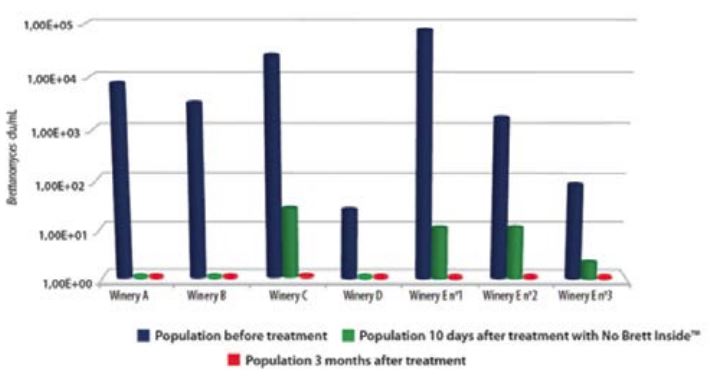

A laboratory study by IOC Nuits-Saints-Georges in Burgundy concluded when used at 4 g/hL No Brett Inside™ was sufficient to totally decontaminate the wine of Brettanomyces (as counted on selective growth media). Similarly, numerous winery-based trials have demonstrated the efficient decrease in Brettanomyces populations (Figure 2).

Recent trials have demonstrated the potential of chitin and chitosans with varying degrees of deacetylation to decrease volatile phenols by up to 26% and significantly reduce the negative sensory impact of these compounds in red wines (Filipe-Ribeiro et al., 2018).

Unwanted wine bacteria can also be removed using chitosan. Bactiless™ (chitosan and chitin-glucan) when used at 20 to 50 g/hL (with a minimum contact time of 10 days) dramatically reduces bacterial populations and prevents bacterial growth in wines, especially after malolactic fermentation, offering an excellent alternative to lysozyme treatment and/or significant amounts of SO2.

Bactiless is also effective against acetic acid bacteria helping to lower viable populations and prevent their growth. Research from Spain has shown that 20 g/hL Bactiless™ reduced Acetobacter populations (Varela et al., 2017).

It is recommended to use Bactiless™ after MLF or in wines not destined for MLF as residual chitosan can also affect the inoculating bacterial strain.

Chitosan as flotation adjuvant

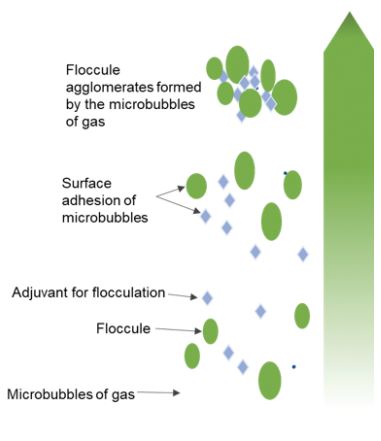

Flotation consists of injecting gas bubbles (e.g. nitrogen or air) into the juice prior to the alcoholic fermentation in order to separate grape solids from the juice. More specifically, the suspended particles stick to the gas microbubbles where they are floated off and separated out.

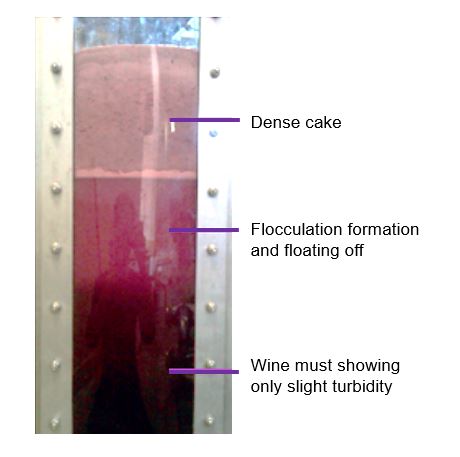

The flotation process requires the application of adjuvants that form floccules through the aggregation of the juice particles and the pectins. The addition of enzymes is also required to break down the pectin bonds, thus helping the particles to float upwards (Figure 3).

While traditional clarification gives a juice that requires from 24 to 48 hours to settle after the addition of fining agents, flotation may take only a few hours (time varies based on winemaking decisions and volumes to treat) to give a juice of around 100 NTU.

The juice is then ready to be yeast-inoculated (assuming a post-floating temperature of 15-16°C).

Among the other benefits, the juice that needs to be treated does not need to be chilled prior to flotation. This drastically decreases the costs associated with energy consumption.

The chitosan flotation aid IOC Qi’Up XC for white, rosé, and red juices is a biopolymer-based formula of chitin derivates that have a very high positive surface charge, and it is this that forms the floccules. Qi’Up XC enhances the flotation speed and performance with which the solid particles separate from the suspension (Figure 4).

Qi’Up XC at a dose of 2 to 10 g/hL provides a genuine alternative to the use of animal products such as gelatine and can be used in conjunction with bentonite for a better clarification and a better compaction of the sediments.

Control of oxidative effects

Excessive oxidation is considered a fault for both red and white wines because it negatively affects colour, red wines turn orange, and white wines turn brown. Prolonged exposure to air can also cause a wine to smell and taste like vinegar due to acetaldehyde converting to acetic acid (Oliveira et al., 2002).

Wine oxidation can be due to enzymatic or non-enzymatic reactions. Enzymatic oxidation occurs in grape must and is associated with the content of hydroxycinnamates (e.g., caffeoyl tartaric acid and p-coumaroyl tartaric acid) and flavan-3-ols.

By contrast, nonenzymatic oxidation occurs primarily in fermented wine and begins with the oxidation of polyphenols containing a catechol or a galloyl group.

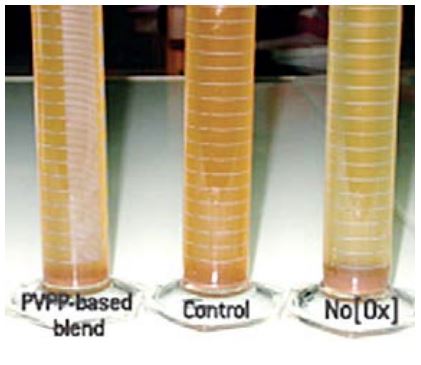

Chitosan is a powerful antioxidant due to its mechanisms against free radicals (Marín, et al., 2019). The chitosan product (IOC No[Ox]) used to control oxidation in juice, as well as white and rosé wines (Figure 5).

Apart from chitosan, No[Ox] also contains bentonite that assists the rapid sedimentation of the complex. Recommended doses of No[Ox] for juice treatments range from 20 to 80 g/hL, while for wine they range from 10 to 60 g/hL.

No[Ox] is primarily used for:

- protecting the colour of white and rosé wines by eliminating iron and copper which are the main catalysers of oxidation, and interacting with polyphenols;

- preserving the aromatic freshness of wines by durably protecting polyphenols against oxidation and efficiently preserving varietal thiols through the anti-free radical properties of No[Ox]; and

- erasing organoleptic defects by eliminating bitterness and oxidative notes, while at the same time preserving sensory and taste properties.

Chelation of heavy metals

The presence of heavy metals (e.g., copper and iron) in wine originate from natural or environmental sources. They can be accumulated by the plant from the soil through the roots, or by contamination due to the techniques and procedures used in the production process (e.g., vineyard sprays or winery equipment). When present at high concentrations, heavy metals can cause stabilisation and safety issues. For instance, an excess of iron (>5 mg/L) may oxidise to the ferric form causing a precipitation of pigmented materials (blue casse) or orthophosphate ions (white casse) (Bornet and Teissedre, 2007).

The presence of heavy metals is also detrimental for grape varieties such as Sauvignon Blanc which are abundant in thiols (e.g., such as 3-mercaptohexan-1- ol and 3-mercaptohexylacetate).

These are sulfur-containing compounds and give wines desirable passion fruit and guava aromas. More specifically, heavy metals can catalyse oxidation reactions which lead to the loss of varietal thiols (Herbst-Johnstone, 2010).

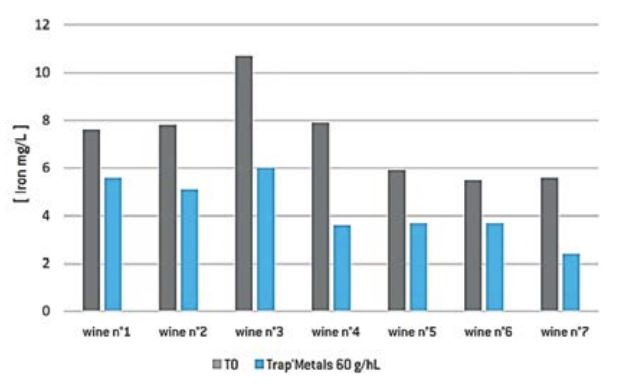

Trap’Metals is a chitosan product used to reduce the concentration of metals in juice and wine. For example, Trap’Metals has been shown to effectively reduce the concentration of iron in Grenache rosé wines by 25-50% (Figure 6). It is a blend of polyvinyl imidazole/polyvinylpyrrolidone (PVI/PVP), chitosan and yeast cell walls, and the synergy of these components help to bind heavy metals such as Cu2++, Fe3+, Pb2+ and others to:

- limit haze caused by metals;

- limit oxidation reactions by eliminating iron and copper;

- preserve the thiol potential of Sauvignon Blanc juice;

- enhance fermentation kinetics; and

- reduce propensity for pinking.

Conclusion

Fungal origin chitosan and chitin-glucan products are an excellent biological option for winemakers to inhibit detrimental microbial developments such as Brettanomyces spp and spoilage indigenous bacteria, assist with flotation, control oxidation, and chelation of heavy metals.

However, it is recommended for winemakers looking to take full advantage of these products to undertake bench trial to determine the optimum product concentration required to achieve the best result for their wine.

Acknowledgements

The authors would like to thank Dr Bertrand Robillard (R&D Manager, IOC) for comments on the manuscript.

References

Bornet, A.; Teissedre, P.L. 2007. Chitosan, chitin-glucan and chitin effects on minerals (iron, lead, cadmium) and organic (ochratoxin A) contaminants in wines. European Food Research and Technology. 226 (4): 681–689.

Filipe-Ribeiro, L., Cosme, F. and Nunes F.M. 2018. Reducing the negative sensory impact of volatile phenols in red wine with different chitosans: Effect of structure on efficiency. Food Chemistry. 242: 591-600.

Herbst-Johnstone, M. 2010. Investigation into the aroma stability of New Zealand Sauvignon Blanc. PhD thesis. The University of Auckland. Auckland, New Zealand.

Marín A.C., Culcasi M., Cassien M., Stocker P., Thétiot-Laurent S., Robillard B., Pietri S. 2019 Chitosan as an antioxidant alternative to sulphites in oenology: EPR investigation of inhibitory mechanisms. Food Chemistry. 285:67–76.

Marín, A.C., Colangelo, D., Lambri, M., Riponi, C., Chinnici, F. 2020. Relevance and perspectives of the use of chitosan in winemaking: A review. Critical Review of Food Science and Nutrition. 1–15.

No, H. K., Meyers, S. P., Prinyawiwatkul, W., & Xu, Z. 2007. Applications of chitosan for improvement of quality and shelf life of foods: A review. Journal of Food Science. 72(5): R87–R100.

Oliveira, C.M., Silva Ferreira, A.C., Guedes de Pinho, P., & Hogg, T.A. 2002. Development of a potentiometric method to measure the resistance to oxidation of white wines and the antioxidant power of their constituents. Journal of Agricultural and Food Chemistry. 50(7): 2121–2124.

Paulin M, Miot-Sertier C, Dutilh L, Brasselet C, Delattre C, Pierre G, Dubessay P, Michaud P, et al. (2020) +Brettanomyces bruxellensis displays variable susceptibility to chitosan treatment in wine. Frontiers in Microbiology. 11:571067.

Petrova, B., Cartwright, Z.M. and Edwards, C.E. 2016. Effectiveness of chitosan preparations against Brettanomyces grown in culture media and red wines. Journal Internationales Sciences de la Vigne et du Vin. 50: 49-56.

Tailandier, P., Joannis-Cassan, C., Jentzer, J-B, Gautier, S., Sieczkowski, N., Granes, D. and Brandam, C. 2014. Effect of a fungal chitosan preparation on Brettanomyces bruxellensis, a wine contaminant. Journal of Applied Microbiology. 118: 123-131.

Valera M.J., Sainz, F., Mas, A. and Torija M.J. 2017. Effect of chitosan and SO2 on viability of Acetobacter strains in wine. International Journal of Food Microbiology. 246: 1-4.

[1]Winequip, Dudley Park, South Australia

[2]Lallemand Australia, Edwardstown, South Australia

[3]Winequip, Reservoir, Victoria

This article was originally published in the May 2021 issue of the Australian & New Zealand Grapegrower & Winemaker. To find out more about our monthly magazine, or to subscribe, click here!

Are you a Daily Wine News subscriber? If not, click here to join our mailing list. It’s free!